Stuart SmithOn the reconstruction of the Bauakademie in Berlin: a contribution from the structural engineers

1.0 Contents

This text describes Karl Friedrich Schinkel’s Bauakademie (Academy of Architecture) in Berlin from a structural engineering viewpoint. The descriptions concentrate on the construction materials used, the structural system chosen, and the construction processes utilized. A short outline of the historical context alongside a description of the rooms and their functions serves to embed the loadbearing structure in its context.

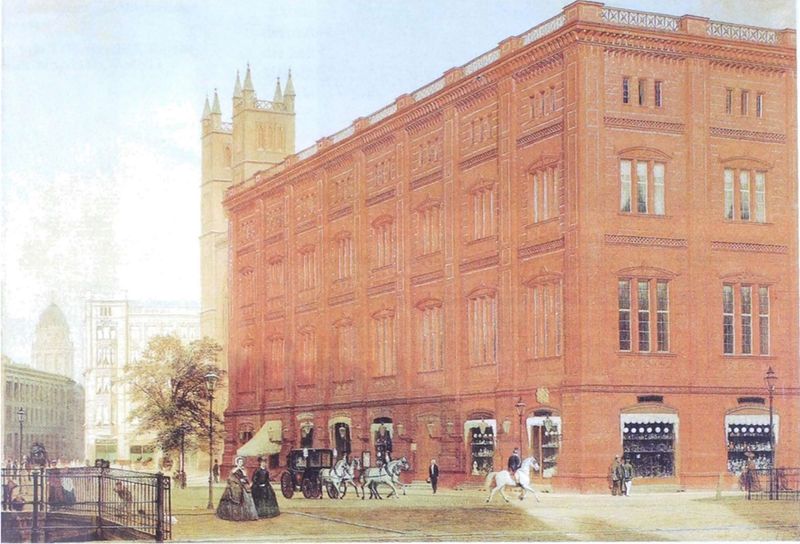

Figure 1.0 “Die Bauakademie”, a painting of Schinkel’s Bauakademie by Eduard Gaertner (1868). From the collection of the Nationalgalerie der Staatlichen Museen zu Berlin, Preußischer Kulturbesitz (Identification number. A II 61 a). Photographed by Jörg P. Anders.

2.0 The History of the Bauakademie

Founded in 1799, the Bauakademie provided a generalist training for Prussian students of architecture. The institution aimed to improve the quality of architecture—and building—in Prussia. Shortly after its founding, it was attached as a department, both in organizational and spatial terms—to the Preußische Oberbaudeputation (Prussian Building Commission), and in 1836, was housed in a new building. This building was erected between 1832 and 1836 on the site of the former Packhof, a storehouse, and a custom and fiscal control office. Based on the architectural plans of Karl Friedrich Schinkel, who was appointed Oberbaudirektor (Director of the Building Deparment) and Head of the Preußische Oberbaudeputation in 1830, the supervision of the construction was entrusted to Emil Flaminius, who in 1836 wrote exhaustive reports in the Allgemeine Bauzeitung about the progress of the construction work and the complicated production of the brickwork—thus providing a wealth of important information about the Bauakademie building.

The Bauakademie was not just a school of architecture but also an architecture museum that was open to the general public. There were shops on the ground floor, the rents for which were intended to finance the running of the school.

In 1884, the Bauakademie, following a merger with the Berliner Gewerbeakademie (business school)—now known as the Technische Hochschule (technical academy)—moved to Charlottenburg. At times the building on the former Packhof site stood empty. In 1911, the rooms on the first floor were used to show the picture collection of the Gemäldegalerie. In 1933 the Schinkelmuseum moved in. In 1945, however, the Bauakademie was heavily damaged by wartime bombing and burnt out.

In 1958 and 1959, an “ideas competition for the socialist redesign of the center of Berlin, capital of the GDR” was held. Although a majority favored the preservation of the Baukademie, it was decided that the building would be demolished. This decision was realized between 1961 and 1963.

3.0 On the Construction of the Bauakademie

The construction of the Bauakademie is determined above all by the technical building process, which focuses largely on protecting the shaped bricks and terracotta elements used. That is the priority.

—Christian Raabe, Eine Ecke der Bauakademie “Zur Rekonstruktion der Allgemeinen Bauschule” Karl Friedrichs Schinkels

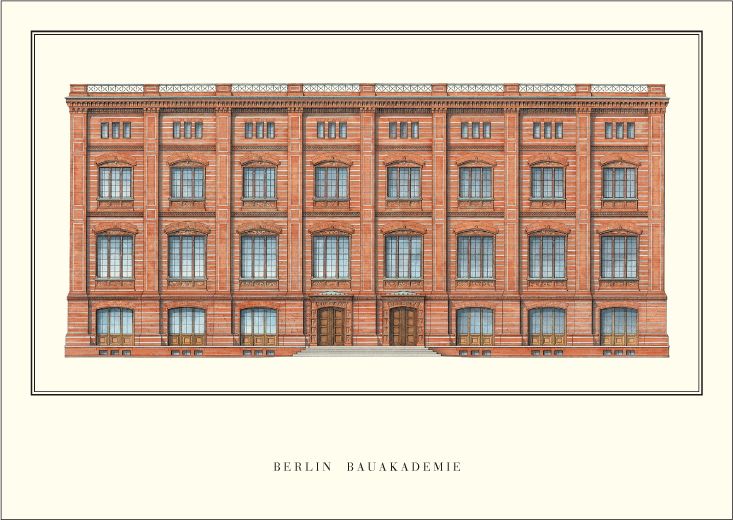

Figure 2.0 Elevation of the Bauakademie. Quelle [1]

3.1 The Building Volume

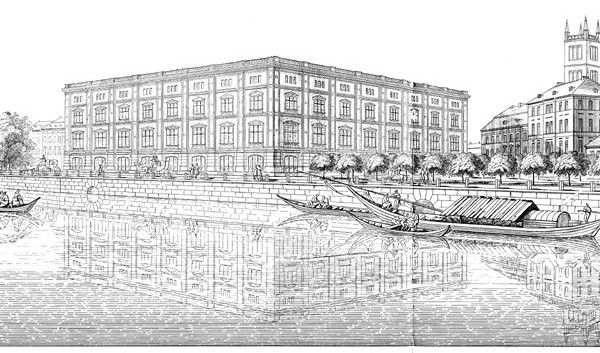

The Bauakademie was a brick building that stood out through its uniform red color and the unusually high quality and precise dimensions of its bricks. The square plan of the Bauakademie, whose sides measured about 46 meters, was based on a regular, eight-part structural grid. This grid was expressed in the facades by projected vertical pilasters. The facade was articulated horizontally by restrained bands, made of distinct courses of glazed bricks. The eaves height of the four-story building was approximately 21 meters. An emphatic cornice clearly defined the eaves. The Below ground, the Bauakademie had a basement that extended under the entire area of the building. Two sides of the Bauakademie were often reflected in the nearby canal, Kupfergraben. The reflection seemed to double the building, making the volume into an almost perfect geometrical cube (Fig. 3).

Figure 3.0 Drawing of the reflection of Schinkel‘s Bauakademie in the nearby canal, Kupfergraben. Source [1]

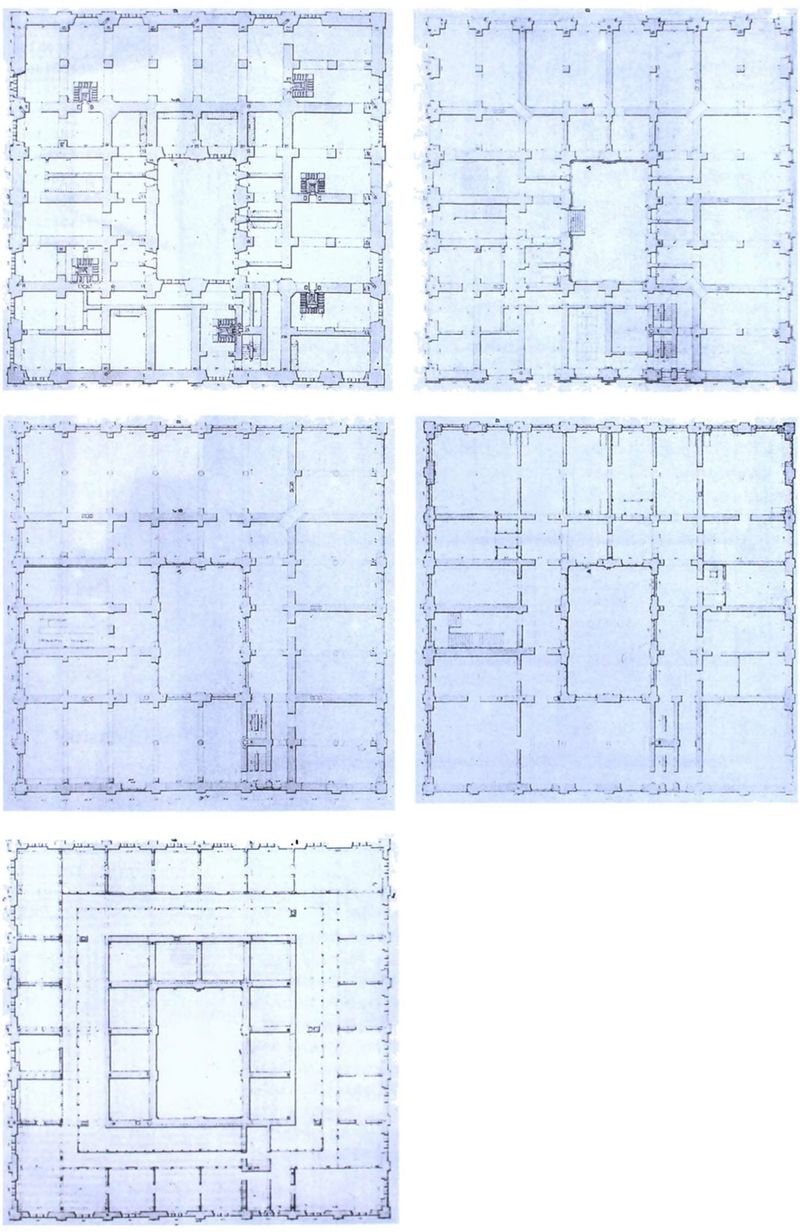

The Bauakademie was a functional building. On the ground floor there were shops—mostly fabric shops—where expensive textiles were stored and sold. Each shop had its own basement space that could be reached directly by a staircase leading down from the salesroom. The rents from the shops were intended to ensure the economic viability of the Bauakademie. The second floor, or the first main floor, was intended to house the Allgemeine Bau-Schule (general architecture school). This floor contained lecture theatres, a drafting room, a library, a reading room, and conference and meeting rooms for the teachers.

The second main floor housed the Oberbaudeputation along with storage areas for plans and files. The third floor was intended for the Director of the Oberbaudeputation and of the Allgemeine Bauschule’s apartment. This is where Schinkel and his family lived. The fourth floor was an attic space, where the roofs sloped down towards a generously dimensioned central lightwell. The basement, besides containing storage rooms for the shops, also included the heating plant for the Bauakademie.

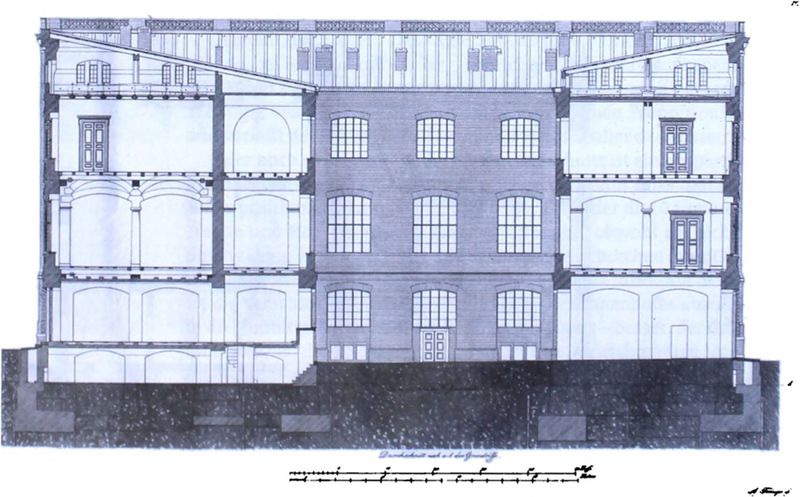

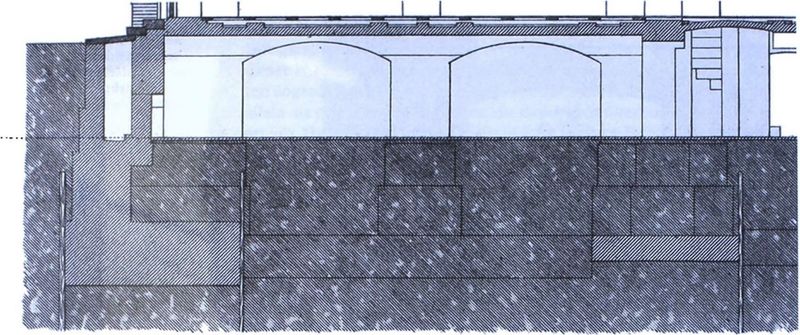

Figure 4.0 Section through Schinkel’s Bauakademie. Quelle [1].

3.2 The Brickwork

The Bauakademie was essentially a brick building. With its exposed brickwork, the building formed part of a Prussian tradition dating back to the twelfth century, the era in which Prussia was established—even if, in stylistic terms, Schinkel found his models in the brick buildings of Italy. Unlike his earlier cultural buildings—the Bauakademie was regarded as a functional building—the bricks were not plastered. They were visible. The quality and singular homogeneity of the color and surface texture of the bricks and terracotta elements used called for skilled craftsmanship and considerable expenditure of time, and became the building’s distinguishing characteristic.

The choice of material was influenced in particular by “the effort to use and shape the native material of fired clay for all parts of the building, to demonstrate its suitability for different kinds of construction and forms and, by perfecting the technical detailing, to encourage new developments in fabricating this material” (Förster, 1836, p. 18). In the 1830s, this design principle was met with criticism and, in the early industrial era, seemed uneconomical. The lengthy production time needed to ensure consistency in bricks determined the nature of the construction and the building phases of the Bauakademie. The goal was to use the expensive construction material in a way that would minimize damage or loss. The erection of the loadbearing structure in the sections that shaped the Bauakademie was intended to avoid stress and uncontrolled cracking in the walls.

The bricks, shaped bricks, and terracotta elements were in a uniform shade of red, which was to become the building’s particular characteristic. The clay-based material used was carefully cleansed of impurities. The surfaces of the bricks were smoothed, and the edges sharpened by hand—a time-consuming process.

All bricks came from the Wentzel brickyard in Königs Wusterhausen, near Berlin. Wentzel built a new brick kiln—the Hoffman kiln—especially for the Bauakademie,and all of the clays used were consistently taken from the same pits and mixed in the same proportions.1 In deciding to commission a single brickyard to manufacture the bricks, Schinkel accepted this would mean a more extended production period. In contrast, the bricks for Schinkel’s nearby Friedrichswerder Church were supplied by three different brickyards, reflected in the variations in the color of the brick facades.

Four production phases determined the quality—the shaping and standardization—of bricks used for the Bauakademie: preparing, shaping, drying, and firing the clay. Alongside the elaborate preparation of the clay, the drying process was carefully directed. Throughout the year the Trocknungs-Schuppen (drying shed) was heated continuously by four stoves through air ducts in the ground so that the temperature was a constant thirty degrees Celsius. The moisture that remained in the unfired bricks created high air humidity in the sheds. Well-insulated with moss, the sheds allowed for slow, even drying. All raw bricks were turned over regularly.

It was pinewood, burned in the kiln, that fired the bricks for the Bauakademie. But before it could be used, this wood had to be stored in a dry, warm place for at least seven years to avoid any moisture from the firewood entering the bricks as it burned. A production failure would have delayed deliveries by up to several months. The use of shaped bricks was moved to later phases in the construction work, as they required a longer production time than standard bricks.

The stringent requirements surrounding the homogeneity of the bricks called for a lengthy and elaborate production process. However, by always using the same workflow, the production was mechanized, influenced, controlled and, precise.

3.3 Structure and Foundations

The Bauakademie is square in plan, with each side measuring approximately 46 meters. The building had four floors and a total height of 21 meters; it had a basement.

As a point-supported structure, it consisted of piers with a few stiffening walls. Therefore, it therefore differs from the standard construction method of the time, was based on load-bearing wall slabs. With few exceptions the piers, external walls (facade) and the foundations and floor slabs were built of brick. The piers transferred the loads vertically, directing them to the individual foundations. Due to the vaulted ceilings to the ground and first floors the piers take a permanent horizontal thrust from a constant load.

The construction and the nature of the building were closely harmonized with each other. The piers erected from the ground floor upwards had to be secured against vibrations and oscillation. Horizontal iron anchors were inserted at ceiling height to minimize the horizontal thrust as far as possible, and to achieve a balance of high shear load forces. The arches and the widths of the vaulting were intelligently optimized, and so, where possible, the loads on the vaults were reduced.

By designing a building whose structural system was based on piers, Schinkel responded to uncertainties about the nature of the ground below, which could lead to uneven settlement. The height and dimensions of the foundations for each pier were determined in accordance with the thickness of the layer of sand over the shifting ground below. The structure and the construction process— reacts sensitively to structural settlement, in terms of material and geometry, allowed for this brick building, designed with large windows, to be built.

The height and dimensions of the foundations for each pier were determined in accordance with the thickness of the sand layer over the uneven building ground.

Figure 5.0 Section through the foundations of Schinkel’s Bauakademie. Quelle [1].

Alongside the difficulties caused by the moving ground, other problems were presented by the high water table level. During the construction work, sheet pile walls were made to prevent water from entering the excavation pit. The excavation pit base was divided into separate areas by smaller sheet pile walls so that any groundwater sources discovered could be partly contained. In addition, masonry hard shoulders were built between the piers and between the individual foundations to seal off water sources. It was essential to prevent moisture rising from the ground to ensure dry storage spaces for costly fabrics stored in the basement storage rooms. Drain walls built alongside the external walls were intended to prevent ground moisture from entering the walls; openings covered with iron grilles allowed a constant air change in the closed basement rooms.

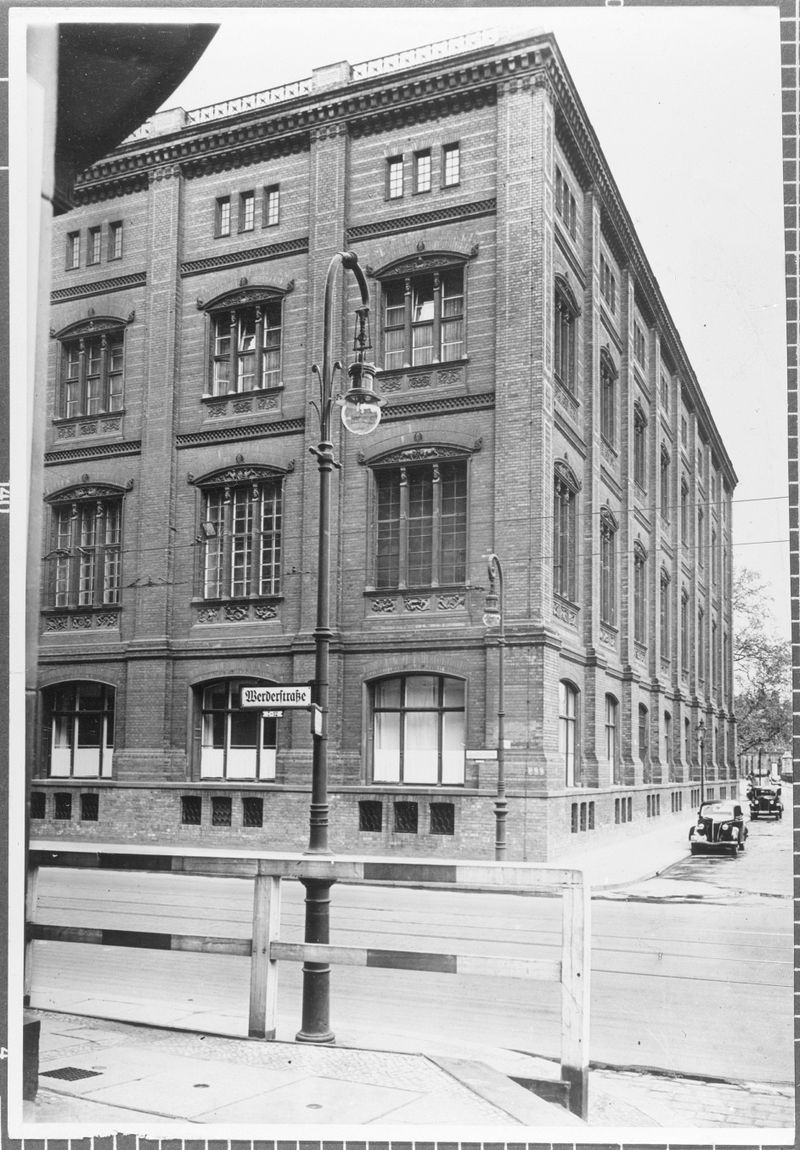

Figure 6.0 Photograph of Schinkels’ Bauakademie. Quelle [1].

During the construction work sheet pile walls were made to prevent water entering the excavation pit. The base of the excavation pit was divided into separate areas by smaller sheet pile walls, so that any ground water

Figure 7.0 Floor plans of Schinkel’s Bauakademie. .

4.0 The Construction Phases

Work on erecting the Bauakademieextended over a period of three years, with a tightly planned building schedule. Two concerns primarily determined the phasing of the construction work: first, the prevention of cracking in the masonry in a building that was sensitive to settlement and protecting the high-quality, expensively produced bricks, and the second was the need to take into account the lengthy production times for the bricks, particularly the shaped bricks and terracotta elements, in scheduling the construction work.

The first year of construction began with the excavation of the building pit and the placing of sheet pile walls to prevent groundwater entry. It was followed the individual brick foundations, external basement walls and piers and hard shoulders, the ground slab, and the ceiling to the ground floor. During this time, the external drains were made, intended to prevent moisture from rising and to ensure dry storage rooms.

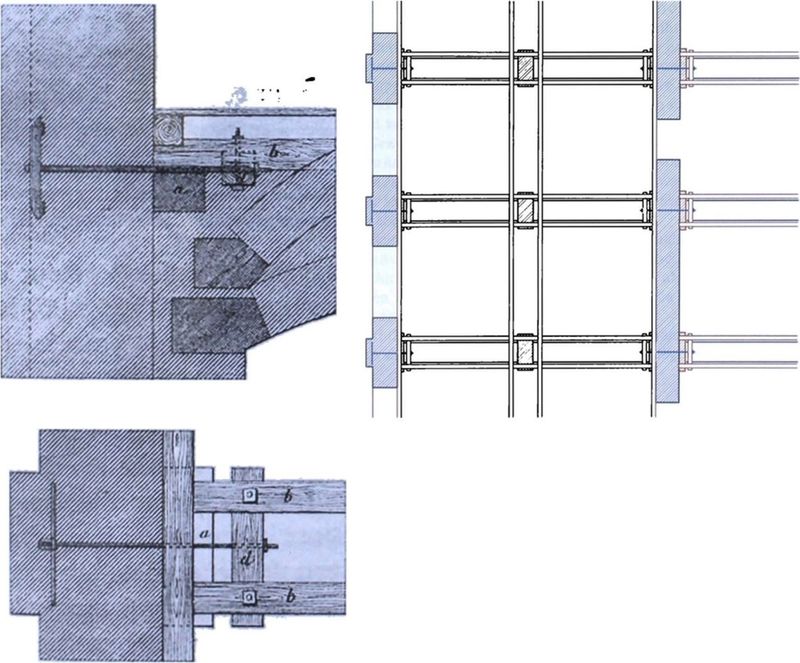

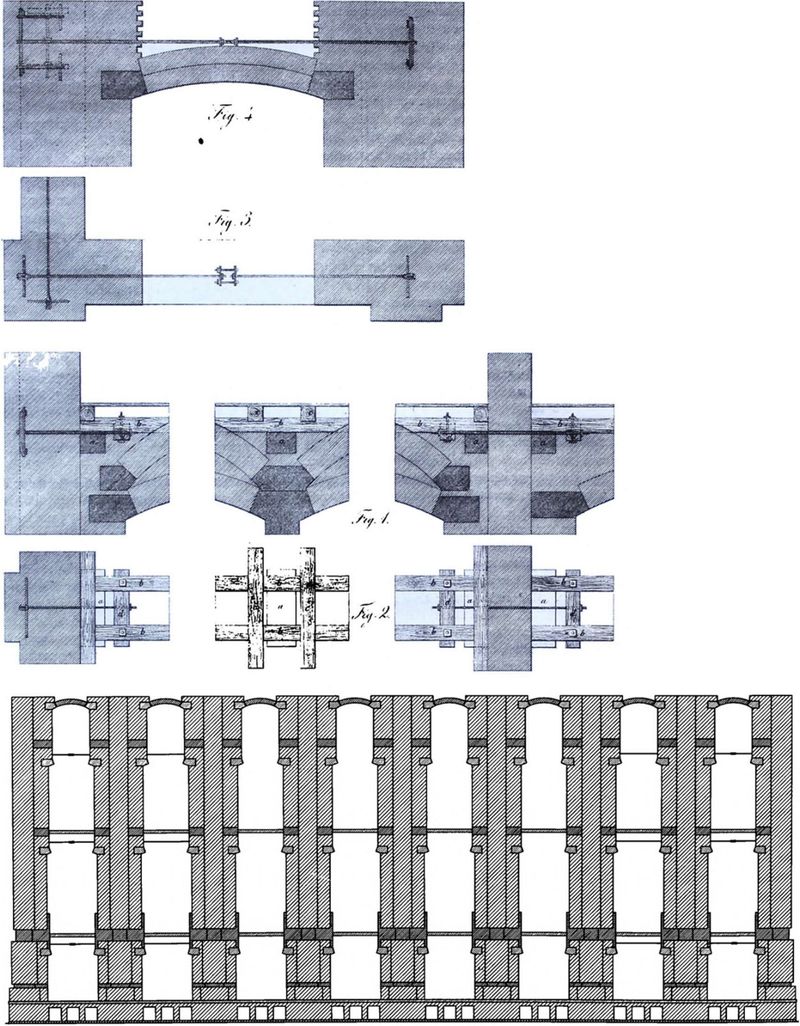

In the second year of construction the vertical masonry piers were erected up to the roof cornice—a height of almost 21 meters. The piers, on each story, three meters high with a thickness of around one meter, became wider as they rose upwards. High-strength sandstone blocks were inserted to hold the arches that were to be inserted later. The floor slabs were not yet inserted at this stage. Instead, when the piers were erected in 1833, a horizontal grid of timber beams was inserted at the height of the later floor slabs—stabilizing the vertical freestanding piers and bracing the external facade piers against the courtyard piers. For each story, these wooden tension members were laid in pairs in the structural grid and were mortised together. In this phase the walls inserted were held in position by the foundations below and by the arch constructions that had already been built there.

The heavy corner piers that took a large share of the horizontal loads were braced against the neighboring pier using horizontal iron straps. These tension straps consisted of two halves at the end of which various vertical and horizontal pins were fixed in the piers’ masonry. In places, these straps had turnbuckles that allowed them to be pretensioned before constructing the arches, enabling the freestanding piers to take sizable shear loads. The turnbuckles also made it possible to react during the construction process to any settlements or deformation.

In the completed building, the turnbuckle system served to take the loads from the vaulted ceilings to the first and second floors, which transferred horizontal loads to the piers through the vault. The arches were only built after the masonry had reached full strength—by waiting for the mortar to harden. The phasing of the construction work allowed the heavy parts of the building to settle in a controlled way and avoided any tearing of the horizontal elements, like ceiling slabs and lintels, that might have occurred due to uneven structural settlement.

After the vertical loadbearing elements had been erected from bottom to top, in the third year, the construction work began at the top and continued downwards. The windows, arches, lintels and parapets were successively installed. Vaulted ceilings were inserted to the first and second floors. On the third floor, where only some of the ceilings were vaulted, simple beams were used that did not transfer any horizontal loads to the piers.

During the first two years of the construction work, the production of the shaped bricks by the Wentzel brickyard had progressed to such a degree that in the third year, the facade in the cornice area could be completed and the terracotta elements put in place. The most complex and largest shapes were used for the roof cornice and in the area of the window lintels. During the third year, the arches and parapets, the cornice brickwork, and the facing bricks that were still missing were inserted, and the windows were fitted.

The outfitting of the interior began in 1835, and on April 1, 1836, with an overrun of just four months, the rooms of the Bauakademie were ready for use.

Figure 8.0 Details of timber anchoring system. Quelle [1]

Figure 9.0 Elevation of facade, during the second year of construction with floor slab anchoring system. From “Ueber den Bau des Hauses für die Allgemeine Bauschule in Berlin,” Emil Flaminius (1836)

5.0 Concepts for the Reconstruction of the Bauakademie in the Twenty-first Century

For open discussion.

Bibliography

Emil Flaminius. Ueber den Bau des Hauses für die Allgemeine Bauschule in Berlin.“, in Allgemeine Bauzeitung, 1. Jg. (1836), nos. 1-4: S. 3-5, 9-13, 18-24, 25-26.

Paul Kahlfeldt. 2016. “Interview Schinkel Bauakademie in Berlin.” In OKLAEY. Retrieved online https://www.youtube.com/watch?v=OT2kS-P5Ib0

Christian Raabe. 2011. Eine Ecke der Bauakademie “Zur Rekonstruktion der Allgemeinen Bauschule.” Karl Friedrichs Schinkels. (Berlin: Edition Imorde)

-

See text by Laila Seewang - Landscapes of Clay

↩