Laila SeewangLandscapes of Clay

Figure 1.0 Landscapes of Clay. Original digital artwork by Molly Jacobs, drawn to accompany this essay. 2020.

Monumental landscapes

Today, the landscape around Königs-Wusterhausen to the southeast of Berlin is barely recognizable as an early industrial landscape—a landscape of clay (figure 1.0). Invisible to the visitor on foot, the imprint of what looks like a Hoffmann kiln is burnt into the ground after decades of constant use, visible from satellite (figure 2.0). Invisible, too, are wells that were needed to feed the machines that mixed extracted clay with water to produce a slurry and, well below the surface, layers of burnt clay from the remains of brick firing centuries ago. Nature has largely covered up the terra-forming that took place as clay was extracted in one location and transported to another to produce curious new additions to this landscape: hills and depressions have replaced a largely flat land. Since the late-nineteenth century, small quarries have been replaced by small lakes having been filled with water, their origins betrayed only by their names—Großer Tonteich (Large Clay Pond), Kleiner Tonteich (Small Clay Pond), and the Pätzer Tonsee (Pätzer Clay Lake)(figure 3.0). This landscape is significant for architecture because it is the extractive landscape that produced Karl Friedrich Schinkel’s Bauakademie (Academy of Architecture), built between 1832 and 1836. This landscape produced the uniform red bricks that would revolutionize eighteenth-century Berlin’s architecture and construction industries and define an architectural monument.

Figure 2.0 Satellite image showing the outline of what is likely a Hoffman kiln to the southeast of Königs-Wusterhausen. Google maps, accessed 6th of August 2020.

The Bauakademie was planned as early as 1830 to bring together all the institutions, scattered across Berlin, responsible for the training of Prussian architects and engineers, and the design and construction of Prussia’s public works.1 Under Schinkel (1781–1841), recently appointed Oberbaudirektor, director of the building department, and Peter Beuth (1781–1853), recently appointed director of the Allgemeine Bau-Schule (Building Academy), it would rise as a freestanding cubic building on a prominent site left open by the demolished customs house across from the Berlin City Palace. This striking urban presence guaranteed the building’s monumental status from the outset. The Bauakademie fit into Schinkel’s plans for the urban redevelopment of central Berlin along the Spree Island: the Altes Museum (1825–1830), the Friedrichswerder Church (1824–1831) just around the corner, and the new customs house (1829–1831).2 Thus, it was constructed to be part of a panorama of urban renewal for the liberated Prussian capital in which Schinkel’s buildings played a primary role.3 Upon completion, Berlin’s most eminent historians, described it as “overwhelming,” and as exceeding the period’s stylistic debates to produce truly original work.4 The building became part of two landscapes: the urban panorama of central Berlin and the invisible, extractive landscape in Brandenburg.

An institutional building of exposed red brick, the building was an eccentricity in the landscape of Berlin’s public architecture that countered a city of stucco facades. A brick structural frame, it challenged the timber frames that had historically supported brick walls. Emil Flaminius, Schinkel’s site inspector, described the structure and construction process in great detail, attributing the architectural result purely in terms of its constructional demands: “it is easy to overlook the fact that the…entire architecture…strives to embody the indigenous fired clay in all parts of the building and, through this, to show [the brick’s] suitability for the various aspects of construction and form and, in its perfection of technical workmanship, to stimulate new advances in the manufacturing process itself.”5

Completed in 1836, the Bauakademie rose briefly, but passionately, as a beacon of a new architectural culture before the revolutionary activities of 1848 started to expose a political divide in Berlin. Enflamed by divisive actions, and even more divisive changes in the reactionary era that immediately followed, exposed brick—a return to humble and sober ‘Prussian’ architecture—was rejected by many bourgeois cultural elites in favor of a safe return to stuccoed, ornamental historicist styles.6 The Bauakademie thus stood, only twelve years old, already as an outlier, a monument to the students of the Bauakademie for whom its lessons did not die. A second and third generation of architects would reignite these lessons that tied architectural aesthetics to a rigorous appreciation of construction honesty. Clay was the indigenous construction material that Brandenburg had in abundance; the absence of stone is what had led to the use of stucco as a substitute to approximate classical architecture. Today, only a handful of masterworks of exposed brick architecture in the ‘Schinkel tradition’ stand out as noteworthy. As Manfred Klinkott, the architectural historian responsible for a vast amount of contemporary knowledge on Berlin’s brick architecture makes clear: “even in our time, brick architecture of the Berlin School has only found value if the example is connected with the name of a generally canonical architect.”7 In Berlin, the Bauakademie is at the top of this list.

The building’s monumental status was repeatedly re-affirmed throughout its lifetime up until its untimely demolition in 1962. For architects following Schinkel, it was a textbook for exposed brick construction that set a precedent for the mastery of local materials. For twentieth-century architectural students and historians, its material expression and structural system make it one of the key monuments that formed modernism’s prehistory. Given the passionate efforts of part of Berlin’s (and Germany’s) architectural community to include the Bauakademie as one of the newly-reconstructed nineteenth-century monuments—a re-monumentalization of Berlin if you will—it is likely that the Bauakademie in some guise will also retain its monumental status well into the future. A corner of the Bauakademie’s façade was recently constructed as a visual lesson about what the city has lost and could potentially have back. Re-building it would resuscitate Schinkel’s inner-city urban project. But it is, in part, the very absence of this building that has allowed it to become a collective monument, as both an individual building and as the centerpiece of Schinkel’s Berlin. It is the building’s function as a screen upon which to project a variety of ambitions and fantasies about the past as well as the future that reflects the ability for architecture to act, as Friedrich Adler hoped, as a ‘monumental illustration of world history,’ an object perhaps even more important for what it represents than what it was.8 So while its status as a monument was never in doubt, what precisely has defined its monumentality has been elusive, shifting. Today, perhaps as then, it is tempting to try and answer this question by looking at a piece of a brick façade. But what we should be looking at is the brick itself.

A Seed

Throughout the constant re-positioning of the reasons for the building’s monumental status, the recognition of its innovation has been unswervingly attributed to its bricks: its structural frame, its construction process, and the way in which the architectural design of its façade reflects these.9 When Adler addressed architects gathered to celebrate Schinkel at the Schinkelfest in 1869, he claimed that the Bauakademie “belongs neither to antiquity, nor even less to the Middle Ages or to the Renaissance. It reveals the transcendence of any narrow historical attachment; it is like a grain of seed, which promises further organic unfolding.”10 If Adler was correct about the building being a seed that would sprout an architectural sea change in the city, it is less clear that its innovation comes of it being the harbinger of a new utilitarian architecture born from a recently-industrializing society. Its innovation also lay in its reinstatement of handmade, craft-based quality and precision at the end of an era of manual labor. It is less interesting to ask which view is correct than it is to ask how the Bauakademie’s resuscitation of the traditions of medieval brick construction was also innovative, or rather, how tradition can be innovative. In order to produce this monument, an entire construction process, the sequences of different trades on and off site, the manufacturing process, the structural system, and the commodification of clay itself had to be realigned. And indeed, it was both a monument to what the newly-mechanizing construction industry could do, as well as to what it would never be able to do again.

Both today and in 1831, Schinkel’s brick was evolutionary, simultaneously a unit of innovation and a material of the past. When Schinkel designed the building, what he also designed was a new material. His brick was a historical bridge: it was looking backward to the better times of the thirteenth century, bypassing centuries to arrive at the flowering of the Holy Roman Empire. German colonization of the northern Slavic lands, soon to become Prussia, had planted medieval brick fortresses, city gates, and monasteries across the region. This brick had been lost to history because of centuries of classically-inspired architecture that utilized stucco to produce monumentality devoid of smaller units: according to Klinkott, the grout that divided the brick façade into smaller units was perceived by architects of the seventeenth- and eighteenth- centuries to destroy the aesthetic unity of architectural form.11 Stucco was then justified functionally to provide the weatherproofing that these less-than-suitably fabricated bricks were unable to do. The Bauakademie has then always been a project in history. But it also represented a potentially new—and Prussian—nineteenth-century architecture that was true to its geographic origins: in a contemporary search for the ‘correct’ style, reviving the medieval craft could provide future orientation. And this striving to bridge between a better past and potentially better future is embedded in its brick and the tortuous process to produce it. That struggle changed the landscape of Berlin’s urban architecture, the construction industry, and Berlin’s immediate hinterland, Brandenburg. The Bauakademie was an index of that landscape.

Three bricks

The Bauakademie is an exercise in brick. It is composed of Quader, a field brick, that formed the brick structural frame, glazed terracotta for the façade (the roof tiles were also terracotta), and terracotta ornamentation designed by Schinkel and produced by sculptors in Berlin. The brick unit determined the depth of ornamentation, which could not cantilever too far from the face of the main structure, and lent itself more to wide, flat bands of lintels and cornices.12 The terracotta ornaments, the original meeting of craft and new manufacturing processes, especially reflected around the windows and doors, immediately received serious attention within architectural circles and, in fact, were the only parts of the structure that survived the bomb damage and subsequent demolition between 1945 and 1962.13 Schinkel designed the individual panels, which were then modeled in the workshop of the sculptor Christian Rauch and cast by Cornelius Germann in Berlin. The terracotta panels installed underneath the sills were displayed as an exhibition to the public before they were installed. Klinkott describes the result of this collaboration between artist, manufacturer, and architect as a Gesamtwerk: a summation of architectural and artistic innovation in producing ornamentation to rival that of any stucco work.14 The lesson here was how ornamentation could be both handmade, a collaboration between architect and sculptor, but could also be mass-produced by industrial means: a meeting of craftsmanship and modernity. This process resituated craft: Schinkel revealed for the city, and Europe, a unique form of Prussian contemporary artistic production that was no longer in competition with European models, but was a mark of cultural specificity. The lesson was directed to the public as much as to the students: the scenes that Schinkel chose to represent on these decorative elements were a narrative complement to Friedrich Gilly’s frieze on the new Mint built across the square: various moments in the history of the development of the art of building. One can assume that the Bauakademie itself was the culmination of this narrative, even if its construction was understood by its students alone.

Schinkel had previously collaborated with ceramics manufacturer Tobias Christoph Feilner to produce a sculpture of the Archangel Michael for the Friedrichswerder church. It was displayed as part of an exhibition in the (previous home of) the Bauakademie in Berlin before it found its place on the building. This collaboration to produce terracotta sculptural elements was not only a lesson in architectural ornamentation but in brick as public art. Exhibiting—an activity receiving its own monumental institution in the form of Schinkel’s Altes Museum, already under construction on the Palace island—was an essential step in re-introducing brick into urban and artistic circulation as a work of art: identifying it with craft and not with brick-as-construction-material. And yet, craft was also subject to the market forces that increasingly influenced the construction industry. Already during the process of producing the terracotta for the Friedrichswerder Church, Schinkel found it necessary to introduce competition to his original collaboration with Feilner because of the expense of the innovative, custom work.

Standardization

The transition of brickwork from purely structural units to ornamentation produced major changes in workflow as well as cultural reception. The brick structural frame dictated that the brick piers were the first part of the building to be constructed, each on their own foundations and settling independently into the swampy soil below. Iron ties were then added, and the connecting vaults filled in between the piers. The floors were added after this, and by 1835, the brick walls filled in the brick skeleton. Barry Bergdoll summarizes this process as anticipating the later American skyscraper frame construction and, just as the skyscraper, it would reshape construction sequence and production, realigning a brick industry that had been geared towards only one method of construction for centuries: the brick wall hidden by stucco. Finally, “the structure was “dressed,” so that as the wooden scaffolding came down the freestanding brick scaffold of the building was clad with brick infill walls and the piers were faced with brick.”15 The building was to show the students of the Bauakademie in form what Schinkel’s incomplete Lehrbüch could not.16 The terracotta ornamentation’s brittleness drove a reverse construction process: the fields of bricks were placed in reverse order, from the top floors to the bottom, so that only after most of the brickwork was laid was the decorative and certainly more fragile ornamental work on the ground floor completed. This was to avoid any bricks falling from above onto the lower portions if work had proceeded from bottom to top, as was usual. Walking past the building at street level, one would notice primarily the exterior bricks used as Verblendsteine (veneer), which were carefully placed in precise rhythmic courses: a surface primarily consisting of perfectly smooth and chiseled pieces of terracotta made from a special blend of two different clays.

Perhaps the least written about innovation, and the most significant for the landscape hiding beyond the frames of Schinkel’s urban Spree panorama, were the fields of unornamented brick. This field brick was also an innovation, perhaps more so than its ornamental terracotta counterpart. Schinkel’s field brick, the brick supplied to the site by the thousands, was a standardized brick, but not yet the normed brick that would later become mandatory for all public works.17 For there to be a normed brick, standardization first had to be introduced. And this was the job of Schinkel’s bricks. If the norm would attempt to homogenize the brick unit across—eventually—the whole country, Schinkel’s attempts at standardization were leveled at producing a brick devoid of individuality for an architecture that demanded a material homogeneity of color, size, density, and impermeability. In order for the brick to become the field of “warm, luminous red” that we appreciate today, it needed to be uniform.18 This was the aesthetic motivation behind its standardization. Each brick could only dissolve into an abstract unit, The Brick, if it surrendered its individuality: its slight differences inherited by uneven heating, hand fabricating, and different clay compositions.

By 1831, Schinkel knew a lot about brick manufacturing, enough to know that intervening in the manufacturing process would be necessary if he wanted a standard product. As director of the building department, he had made suggestions that altered the Lehr-Eskadron military barracks and prison design completed in 1818 to ensure it would be an exposed brick structure. He built a brick lighthouse in Rügen between 1825–26 and a private residence with a brick façade for Feilner in Berlin completed in 1829. For the Friedrichswerder Church, which was completed just before construction on the Bauakademie began, he specified a custom brick to be achieved, and supplied, from two manufacturers. The bricks of the Friedrichswerder ranged between a light yellow and a dark brown and the occasional blue-black and greenish brick. Seven years later, the Bauakademie’s bricks’ individuality dissolved to create a uniform field of warm red: a plastic surface broken up by not by the brick unit but by horizontal bands of violet glazed bricks set between the structural piers. Colors now followed a structural logic, not the logic of each unit. The change from polychromy to uniformity was one of process, from bricks supplied by multiple regions and firing conditions to a new precision and standardization in the production process.19

Landscapes of clay

What we know of the brick production for the Bauakademie comes to us via the writings of Flaminius: not just his description of the Bauakademie’s construction, but also his article over brick production in Prussia.20 It is he who mentions that the Wentzel brick factory was chosen to produce the bricks—all the field bricks—for the Bauakademie. To produce enough bricks for an entire building was a significant and unprecedented task. At the time, bricks for large construction projects would normally be attained from multiple brickyards, no one manufacturer being able to supply bricks in this quantity. Brick production had historically been a side-product of larger estates or towns in Brandenburg. Many villages had open brick ovens, and bricks would be made, as needed, for local construction projects. Brick production at mid-century was still largely a seasonal occupation. In summer, workers would crowd into the small villages and towns of brick-producing Brandenburg for brick making, by hand. Around Berlin, this was primarily the region between Rathenow, Glindow, and Zehdenick. By 1850, demand for brick had risen significantly in response to Berlin’s rapid industrialization—bricks being also used for most infrastructural structures—and transporting excess bricks to the Berlin market began to shape new transport flows. Smaller brickyards began to operate collaboratively to meet these demands, but something like Wentzel’s brickworks was still the exception. Since most of this large-scale construction was generated by infrastructural and industrial construction, it was unimportant if the bricks varied slightly. The Bauakademie was the first building for which it was deemed essential that one brickyard produces all bricks precisely to achieve standardization.

The aesthetic and functional demands placed on the bricks for the Bauakademie sent reverberations of change through this landscape of small, decentralized, brick production. In a kind of reciprocal regional development produced by the pressure of supplying larger and larger quantities of bricks, and the development of rail transport to get bricks to Berlin, certain towns that were favorably situated to both clay deposits and rail infrastructure began to specialize in brick production for Berlin. Once a side project in a village whose industries served a wide variety of local needs, brick would soon develop into a mono-industry.

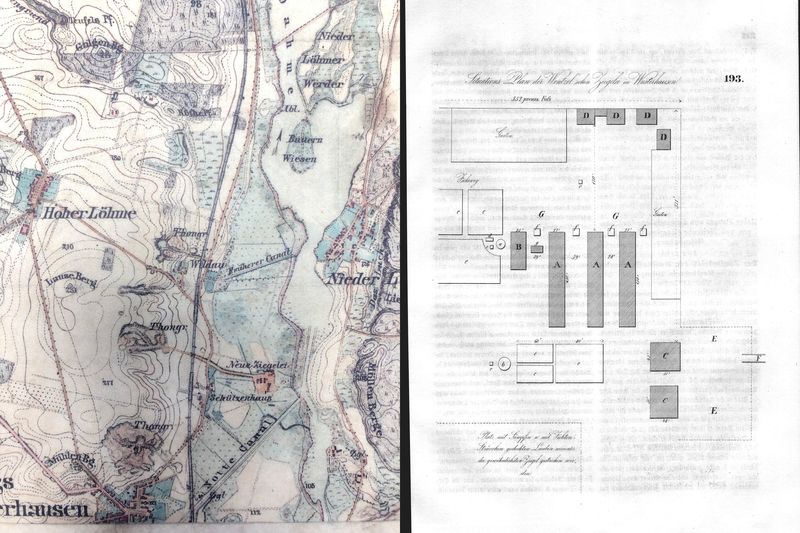

The Wentzel factory was located not in the northern and western clay regions of Brandenburg, but in Königs-Wusterhausen, a town that only later specialized as a brick production center.21 The Wentzel brickworks was one of the earlier brickworks of the town, known locally in chronicles and on maps as the Neue Ziegelei, the New Brickworks (figures 3.0 and 4.0).

Figure 3.0 Map showing the Neue Ziegelei to the north of Königs-Wusterhausen and a series of clay pits to the west of the railway line. Staatsbibliothek zu Berlin, Map Department, IIICKartN 729_Blatt 1977 von 1869.

Figure 4.0 Site plan of the New Brickworks. From Emil Flaminius, “Ueber die Ziegel-Fabrikazion in den preußischen Provinzen,” Allgemeine Bauzeitung 21 (1838): 193

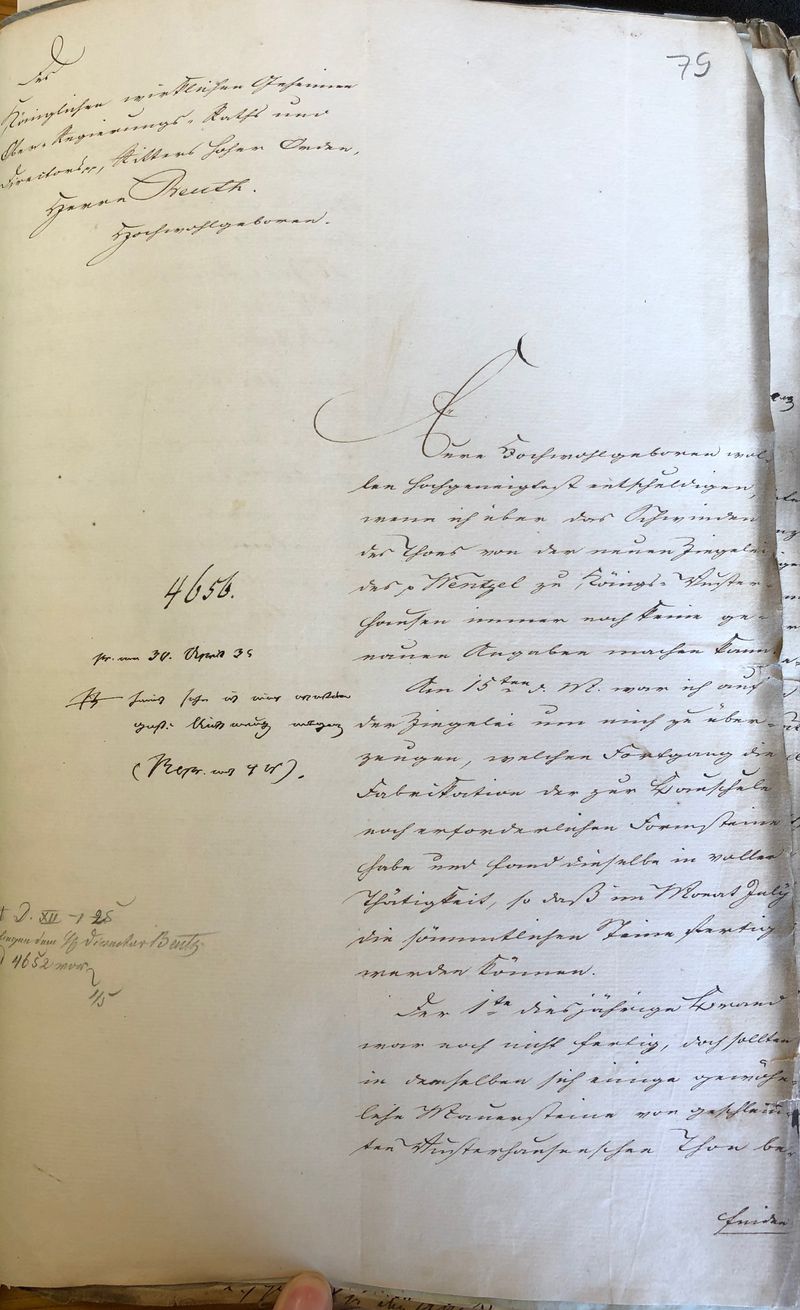

In 1835 the Bauinspektor (building inspector) Bürde went to visit the new brickworks in the town in order to report back to Beuth upon “the improvements and advances in brick fabrication” in Prussia (figure 5.0).22 It seems that Wentzel, a manufacturer from Stolpe near Birkenswerder, had rented the works shortly before this visit from the Gutsbesitzer (estate owner) Mencken, who had most probably been previously running the works as a side business. Wentzel implemented some key changes in the manufacturing process that attracted Bürde’s attention and, presumably, were then communicated from Bürde to Beuth and Beuth’s design partner for the Bauakademie, Schinkel, just in time for the construction of the new building.23

Figure 5.0 Report from Beuth on the Wentzel brickworks in Königs-Wusterhausen, April 1835. Geheimes Staatsarchiv Preußischer Kulturbesitz I. HA Rep. 120 Ministerium für Handel u. Gewerbe DXII 1, Nr. 25 Bd. 1, “Akten betreffend die Verbesserung und Beförderung der Ziegel Fabrikation”: 79.

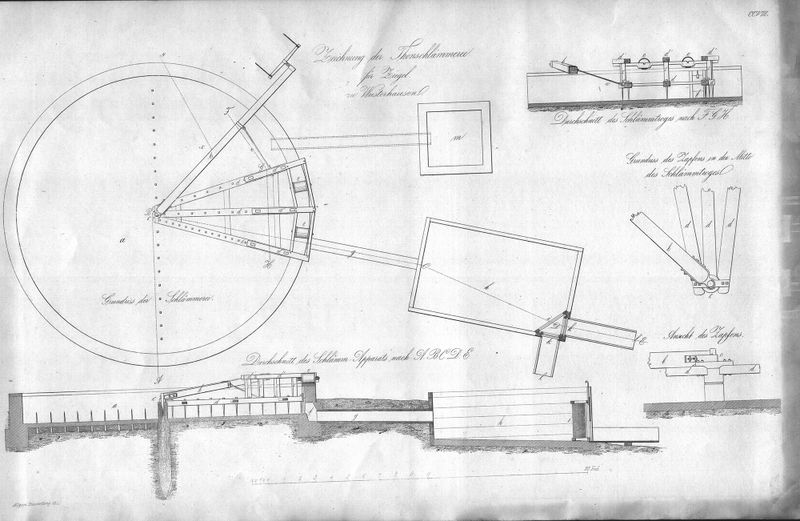

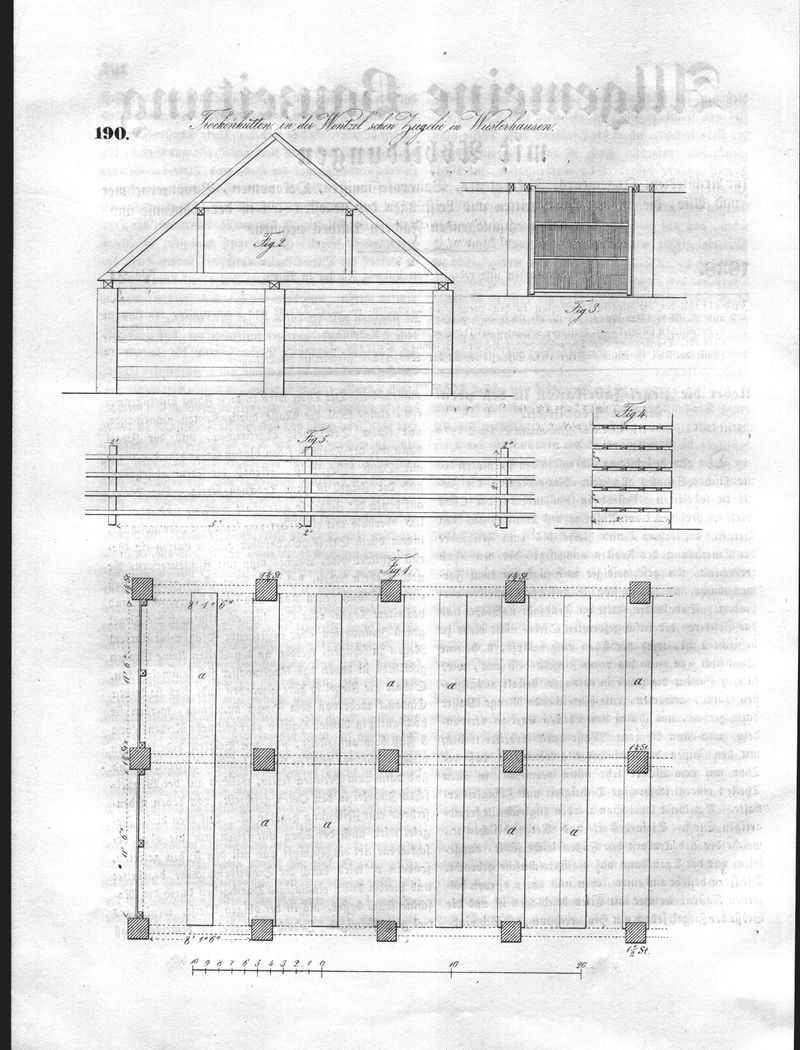

Traditionally, the first step in brick production was to extract clay from the ground in early winter to expose the mass to frost so that water could enter the material, and the spring thaw could then open up cracks in the material, making it easier to mix with water. The Wentzel brickworks augmented the human labor of mixing clay and water by foot with a machine that would create a more even slurry of wet clay to be molded into bricks (figure 6.0). Nonetheless, the human hand—or foot—was still relied upon to catch small alien materials in the slurry. Drying, normally outdoors even if protected from the worst of the spring rains by an arbor, would also be controlled at the Wentzel works. A new drying shed was built for the project designed to dry all bricks as evenly as possible with piped hot air circulating at a constant 30degrees Celsius throughout winter and summer (figure 7.0).24 After drying, special attention was given to the firing process. Wentzel received a state grant to build a new oven for firing the Bauakademie bricks. According to archaeological evidence, it was most likely an oven that resembled a modified Kasseler Flammofen, a kind of evolutionary step in between the pre-industrial Altdeutsche Ofen (Old German Oven) and the Hoffmanische Ofen (Hoffman kiln) of the 1860s.25 The Kasseler Flammofen had been developed near Kassel and was renowned for producing clean bricks due to the separation of the combustion material from the bricks by a perforated wall, which held back a lot of the residue produced in combustion.26 In furnaces that burned coal, an ash residue would often fall on bricks unevenly, causing color and density variation as the brick was heated and its water content evaporated. This wall reduced the amount of ash falling on bricks.

Figure 6.0 New clay slurry mixer at the New Brickworks. From Emil Flaminius, “Ueber die Ziegel-Fabrikazion in den preußischen Provinzen,” Allgemeine Bauzeitung 21 (1838): 57.

Figure 7.0 New drying shed at the New Brickworks. From Emil Flaminius, “Ueber die Ziegel-Fabrikazion in den preußischen Provinzen,” Allgemeine Bauzeitung 21 (1838): 190.

For the Bauakademie, additional efforts were made to mitigate discoloration from falling ash by placing bricks on their long sides so that at least the surface that was exposed would remain as clean as possible. Additionally, bricks were fired using pine wood dried for at least seven years to ensure that the increased levels of humidity emanating from younger wood could be reduced to a minimum.27 Since the wet clay itself also produced humidity as it was being dried, dry wood at least restricted the number of variables at play. If various parts of the brick were exposed to differing humidity levels, there was again the risk of discoloration, or uneven coloration, and cracking. It would not be until the Hoffman kiln was patented in 1858 that these harbingers of change would be cemented in Brandenburg’s productive clay landscape. A fully systematic process of artificial drying and burning would remove the clay from the influences of ill-tempered climate, and imprecise human hands, and standardized bricks could be fired all year round. And once a brickyard was expected to operate continuously to produce bricks in line with the pace of construction, seasonal work no longer made sense.

Landscapes of commodity

Although the Wentzel brickworks were based in Königs-Wusterhausen, south of Berlin, they would create bricks combined clay from Stolpe, about 20km north of Berlin and only 5km from the heart of yellow clay territory at Birkenwerder, and clay from a pit in Rathenow, the heart of red clay territory 80km west of Berlin.28 The difference in the geologies of these two parts of Brandenburg directly impacted the reception of Schinkel’s Bauakademie today: the color that radiates from Eduard Gaertner’s memorable 1868 paintings of the building were produced by the precise mixing of these clays. These architectural demands were what drove the changes to the brickyard: the Wentzel brickyard not only had to manufacture all the bricks themselves but also had to ensure that, over time, the precise combination of the two clays was consistent. This consistency was perhaps even harder to achieve than the quantity. Moving raw clay across the region, instead of moving seasonal workers or the bricks themselves, brought new communication lines into Brandenburg. Cross-country transportation of goods connected to new places—places that were not determined by watercourses but by geology. Transporting from the clay pits to the brickyard over 70km in regional Brandenburg amounted to a scaling-up of the productive landscape, refining and selecting of areas of Brandenburg in the constitution of a more desirable product. An aesthetic motivation demanded that the brick be composed of a mix of different quality clay materials and not merely an accidental reflection of its origins. Once the brick was no longer a specific index of its geographical origin, it became a statistical reflection of a certain quality: it was representative of an abstract commodity with certain desired characteristics.

Cultural landscapes

This detachment of the brick from the earth—by being a hybrid unit composed of clay from two regions and manufactured in a third—makes little difference to its performance as a material unit. But Schinkel had selected the brick for both its material and cultural qualities. The brick was soon to rise to the heights of a cultural symbol for Berlin and Germany. This was thanks in part to Schinkel’s architecture, but also to a series of preservation efforts radiating out from nineteenth-century Berlin to evoke the medieval Prussian Kingdom. Although Schinkel’s conviction of brick’s cultural qualities developed out of his encounter with brick factories on a trip to England with Peter Beuth and to Bologna and Ferrara in 1805, it was reinforced by the local influence of his mentor David Gilly who inspired him to join the early efforts to preserve the medieval Marienburg fortress in Prussia (now Poland): work that was certainly conceived in patriotic terms.29 When the first Conservator of Preservation, Ferdinand von Quast, published on Prussia’s red brick medieval inheritance in 1850, it was well-established in art historical circles that red brick Gothic architecture was the region’s authentic architectural style, owing largely to a lack of natural stone reserves. “Schinkel very consciously chose brick as a vernacular material, not only for economic reasons, but also to promote and resuscitate a special construction of north German (brick) architecture, both in the color and the weather-resistance of the façade.”30

Schinkel sent his masons off to see first-hand the examples of medieval brick architecture in Brandenburg and to study the brick construction techniques at the Cloister at Chorin.31 To Marienburg and Chorin would soon be added art-historical interests in the medieval inheritance of Brandenburg at large: the town halls of Frankfurt (Oder) and Jüteborg, the cathedral of Havelberg, Stendal, Königsberg (Neumark), the monasteries at Lehnin, and Neuzelle, churches in Tangermünde, Rathenow (St. Maria u. Andreas), Brandenburg (town), Prenzlau and Angermünde, and city gates in Brandenburg (town), Stendal, Ruppin, Prenzlau, and Templin.32 In these narratives, the red brick was authentic because it tied the Prussian culture to its soil. The red brick was the unit of authenticity in an era otherwise plagued by discussions of what style to build in.33 The irony of Schinkel’s red bricks paving the way for a new architectural identity to Berlin was that this very brick was no longer tied to its location. It was industrial Berlin’s brick: a mixed commodity from the surrounding industrializing region beginning to orient itself towards the capital.

By the 1870s, the industrialization of Berlin’s brick industry was largely complete: the Hoffman kiln, major infrastructure, municipal architectural—and infrastructural—building program that demanded uniform red bricks for hospitals, abattoirs, schools, and churches, and the introduction of the Normalformat for bricks, would stamp lasting change onto Brandenburg’s clay landscape. Brickworks were less in number but produced more bricks, and certain locations like Zehdenick were fortuitous in this productive geology delaminated from the soil and oriented towards Berlin. The new industrialized construction processes born of this new alignment would only come to a halt with World War I.34 It is notable that, precisely in the 1870s, just as the landscape of production congealed into a stable relationship, the unnamed Baumeister who followed in Schinkel’s footsteps and produced the immense amount of municipal architecture of the late-nineteenth-century chose to turn away from this modernized brick, from Schinkel’s brick. A desire to return to the hand-made brick, for its weather resilience, ease of simple working into ornamental pieces by hand, and durability—in removing the glazed, terracotta surface to produce a consistently dense brick—was made explicit. The influence of political and cultural narratives, a desire for authenticity, and simplicity of Kultur in the face of advanced Civilised methods (like terracotta perhaps) were evident.35 At the crossroads of craft and technology, Schinkel’s brick came into question only a quarter of a century after it produced these monumental changes.

Reconstructed landscapes

It has been eloquently stated that “the Bauakademie was not a document of the production capacities of the period, but rather an anticipation of them, a goal which could only be attained with immense care and on-going commitment.”36 Striving to meet these demands was responsible not for the industrialization of the Brandenburg landscape as a whole, but it was responsible, in large part, for the form that that industrialization took in Brandenburg’s clay regions. In this light, the Bauakademie was innovative not because it was an object produced by the newly industrialized construction industry, but because it preceded it and laid down the parameters by which mechanization of the brick industry would be achieved. It is an example of hand labor being expected to meet, as yet non-existent, mechanical precision and homogeneity. It was innovative as a process, not as an object. And this process led to a new urban landscape that would link nineteenth-century Prussia to its medieval origins through authentic construction techniques and an architecture of red brick, and, in attempting to create this, to the emergence of a new territory structured around the production of clay-as-commodity. If the question today is whether or not to reconstruct the Bauakademie, it is useful to ask how we delimit the boundary of this architectural monument, and whether design innovation rests in a façade, a brick, a landscape, or the entire construction process. This landscape of clay, the unbuilt context of the Bauakademie, is a landscape that itself was also designed—and it is a landscape that, too, is barely reconstructable.

-

Christian Raabe, Eine Ecke der Bauakademie. Zur Rekonstruktion der “Allgemeinen Bauschule” Karl Friedrich Schinkels (Berlin: Edition Imorde, 2011), 13.

↩ -

In 1972, Hermann Pundt referred to Schinkel’s ‘environmental design’ of central Berlin, as opposed to concentrating on the impacts of singular buildings, the Bauakademie being only the last in a series of architectural works that formed a new urban environment. Hermann Pundt, Schinkel’s Berlin: A Study in Environmental Planning (Cambridge, MA: Harvard University Press, 1972), 106–195.

↩ -

The use of ‘panorama’ here references Kurt Forster’s position in his essay, “Schinkel’s Panoramic Planning of Central Berlin,” Modulus 16: The University of Virginia Architectural Review (1983): 62–77. Schinkel’s urban plans for Berlin, many of which were unsuccessful in their original form, must be seen in light of the institutional and governmental reforms put into place following the liberation of Berlin from the French occupation between the years of 1806 and 1815. During 1806 and 1809, the royal governance, having fled Berlin before Napoloen’s arrival, ruled the Prussian province from Königsberg. For a clear and insightful summary of this period see Ilja Mieck’s chapter, “Von der Reformzeit zur Revolution,” in Wolfgang Ribbe, ed., Geschichte Berlins Vol. 1 (Munich: C.H.Beck, 1998).

↩ -

Franz Kugler, “Karl Friedrich Schinkel: Eine Charakteristik seiner künstlerischen Wirksamkeit,” Kleine Schriften und Studien zur Kunstgeschichte, vol. 3 (Berlin 1854 [1842]): 327, cited in Barry Bergdoll, Karl Friedrich Schinkel: An Architecture for Prussia (New York: Rizzoli, 1994), 203; Friedrich Adler, “Schinkelfestrede,” Zeitschrift für Bauwesen 19 (1869): 473.

↩ -

Emil Flaminius, “Ueber den Bau des Hauses für die allgemeine Bauschule in Berlin,” Allgemeine Bauzeitung 1, Nr. 3 (1836): 4. “Es ist leicht zu übersehen, daß die Gestaltung des ganzen Planes und der ganzen Architektur neben jenen Grundbedingungen und der Durchführung des flachen Gewölbe-Systems noch aus einem andern Motiv hervorgegangen ist, nämlich dem Streben, das einheimische Material des gebrannten Thons in allen Theilen des Gebäudes zu verkörpern und durchzubilden, seine Anwendbarkeit für die verschiedenartigsten Konstrukzionen und Formen zu zeigen, und durch Vervollkommnung der technischen Bearbeitung zu neuen Fortschritten in der Fabrikazion selbst zu ermuntern.”

↩ -

Manfred Klinkott, Die Backsteinbaukunst der Berliner Schule. Von K. F. Schinkel bis zum Ausgang des Jahrhunderts (Berlin: Gebr. Mann, 1988), 21.

↩ -

Ibid.

↩ -

Friedrich Adler, “Die Baugeschichte von Berlin,” (speech, Germanische Museum zu Nürnberg, Nurnberg, Germany, February 6, 1861).

↩ -

Raabe formulates the central question at the beginning of his publication: “worin besteht die konstruktive Innovation?” In Raabe (2011): 11.

↩ -

Adler (1869): 473.

↩ -

Klinkott (1988): 13. “Doch seit der Renaissance und dem Barock wurde das Mauerwerk mit Putz verkleidet, da man das dichte Fugennetz als störend empfand und sich die Einzelformen der antiken Überlieferung aus dem kleinformatigen Ziegel kaum herstellen ließen.”

↩ -

Ibid, 14.

↩ -

Bergdoll (1994): 203.

↩ -

Klinkott (1988): 56.

↩ -

Bergdoll (1994): 201.

↩ -

The Lehrbuch (textbook) was a collection of sketches and writings on architecture unpublished in Schinkel’s lifetime. Goerd Peschken inherited the project from Schinkel scholar Paul Ortwin Rave to organize Schinkel’s unpublished material into a new publication, which appeared in 1979; Karl Friedrich Schinkel, Das Architektonische Lehrbuch: Karl Friedrich Schinkel Lebenswerk, ed. Goerd Peschken (Munich: Deutscher Kunstverlag, 1979).

↩ -

The Normalformat (or Reichsformat, later to become DIN 105) would only be established in 1869. By 1872 the Reichsformat was introduced to standardize the brick into a 25cm x 12cm x 6.5cm unit.

↩ -

Klinkott uses this term to describe the colour of the Bauakademie. Manfred Klinkott, “Die Bauakademie,” in Staatliche Museen zu Berlin, Preußischer Kulturbesitz, Karl Friedrich Schinkels Berliner Bauakademie. In Kunst und Architektur. In Vergangenheit und Gegenwart (Berlin: Nicolai, 1996): 14; Barry Bergdoll also pointed out the role that brick played in the early standardization of building materials in his review of Manfred Klinkott’s 1988 publication. Barry Bergdoll, Manfred Klinkott, Die Backsteinbau der Berliner Schule, vom K. F. Schinkel bis zum Ausgang des Jahrhunderts” Journal of the Society of Architectural Historians, Vol. 53, No. 1 (1994): 104.

↩ -

Erik Forssmann states that the Formziegel for the Friedrichswerder Church were supplied both by the Feilner brickworks and the Royal Brickworks in Joachimsthal. Erik Forssmann, Karl Friedrcih Schinkel. Bauwerke und Baugedanken (Munich and Zurich: Schnell & Steiner, 1981), 132; Raabe (2011): 99.

↩ -

Emil Flaminius, “Ueber den Bau des Hauses für die allgemeine Bauschule in Berlin,” Allgemeine Bauzeitung 1 (Wien) (1836): 1-5, 9-24, 18-24, 25-26; Emil Flaminius, “Ueber die Ziegel-Fabrikazion in den preußischen Provinzen,” Allgemeine Bauzeitung 1 3 (Wien) (1838): 189-193, 197-200.

↩ -

Brick production took off after 1860, by which time industrial manufacturing had already reshaped the brick industry. At its highpoint, Königs-Wusterhausen had between 46 and 48 brickyards. Wentzel’s activities at the New Brickyards predate and predict these changes.

↩ -

Geheimes Staatsarchiv Preußischer Kulturbesitz I. HA Rep. 120 Ministerium für Handel u. Gewerbe DXII 1, Nr. 25 Bd. 1, “Akten betreffend die Verbesserung und Beförderung der Ziegel Fabrikation.” Beuth writes about the ‘Wentzel’ brickworks on pp. 79, 80 and 89.

↩ -

It is likely that deforestation around Stolpe, caused in part by brickworks like Wentzel’s previous brickworks there, were part of the reason for Wentzel’s move to Königs-Wusterhausen, which was north of the large Königlichen Forst Hammer and other forests. Horst Hartwig, Die Ziegelei in Stolpe bei Berlin. Die Stolper-Ziegelei und Werder-Ziegelei, 1825-1900 (2020); http://www.horsthartwig.de/stolpe_ziegeleien_pannwitz_veltheim_architekt_hermann_wentzel_emilie_heckmann_opti.pdf (accessed 18 May, 2021).

↩ -

Flaminius (1838): 191.

↩ -

This is documented at the Dahmelandmuseum in Königs-Wusterhausen, according to the nearly thirty years of archaeological research into local brick history by Herr Heinz Flieger, to whom I am indebted for sharing his knowledge.

↩ -

Ludwig Klasen, Grundriss-vorbilder von Gebäuden aller Art. Abth. XV Theil 1: Bierbrauereien, Spiritusbrennereien, Stärke-, Dextrin-, Traubenzucker- und Sago-Fabriken (Leipzig: Baumgärtner’s Buchhandlung, 1896): 2384.

↩ -

Raabe (2011): 48.

↩ -

Klinkott (1988): 56; Klinkott (1996): 15.

↩ -

Axel Klausmeier, “…voll von den vollendeten Werken unserer blühenden deutschen Vorzeit..,” “Denkmalpflege als patriotische Aufgabe in der ersten Hälfte des 19. Jahrhunderts,” (Lecture, Cottbus University, 2–4 March, 2006).

↩ -

Klinkott (1996): 12.

↩ -

Klinkott (1988): 39.

↩ -

Friedrich Adler, Mittelalterliche Backstein-Bauwerke des preußischen Staates Vols.I and II (Berlin: Ernst & Korn, 1862 and 1898).

↩ -

Heinrich Hübsch, In welchem Style sollen wir bauen?(Karlsruhe: Müller’schen Hofbuchhandlung und Hofbuchdruckerey): 1828.

↩ -

Carston Benke, “Die Ziegelindustrie in Brandenburg im späten 19. und frühen 20. Jahrhundert: Auswirkungen ländlicher Industrialisierung am Beispiel der Ziegelregion um Zehdenick.” Masters dissertation, Institut für Geschichtswissenschaften, TU Berlin, 1998: 12.

↩ -

For more on the opposition of German Kultur to French and English Civilisation, see Elias Norbert’s work on the Civilising Process. Eric Dunning and Jason Hughes, Norbert Elias and modern sociology : knowledge, interdependence, power, process (London: Bloomsbury Press, 2013), 82–87.

↩ -

Klinkott (1996): 14.

↩